Suppply Chain Management

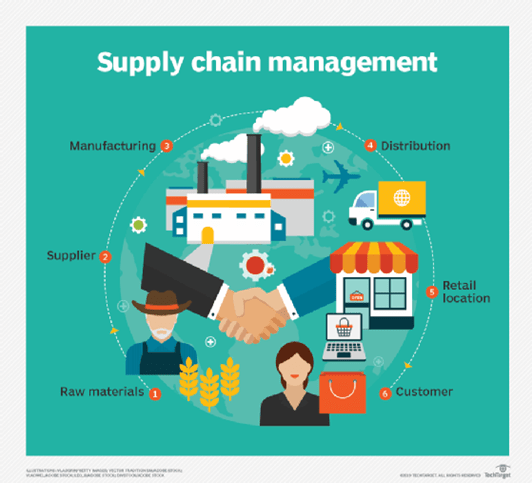

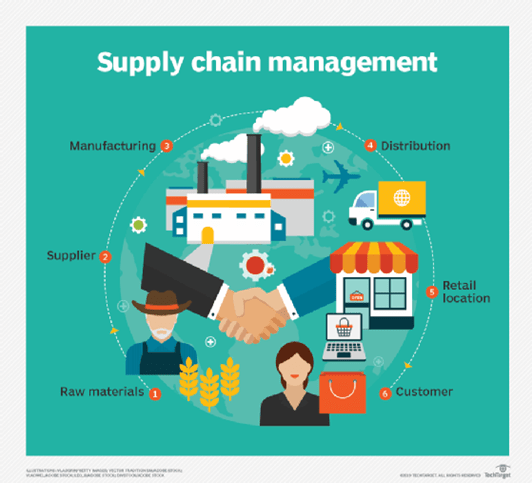

The management of the flow of goods and services between organizations and locations is known as supply chain management (SCM). The movement and storage of raw materials, inventories for work-in-progress, finished goods, and the complete order fulfilment process from the point of origin to the site of consumption can all be included in this. Networks, channels, and node firms that are interconnected, interrelated, or linked together provide the goods and services that end users in a supply chain need.

The term “design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging global logistics, synchronizing supply with demand, and measuring performance globally” has been used to describe supply-chain management. Industrial engineering, systems engineering, operations management, logistics, and procurement are all significantly utilized in SCM practice, Information technology and marketing are combined,[6] and a multidisciplinary, multimethod approach is sought after

Marketing channels are crucial to supply-chain management, The subjects of sustainability and risk management, among others, are the focus of current supply-chain management research.

Supply chain resilience is a key idea covered in SCM. Some claim that topics like as the “people dimension” of SCM, ethical concerns, internal integration, transparency/visibility, and human capital/talent management have not received enough attention on the research agenda thus far. SCM refers to the wide variety of tasks necessary to efficiently plan, manage, and carry out a product’s movement from raw materials to production and distribution. SCM includes coordinated planning and Demand planning, sourcing, production, inventory management, and logistics—or storage and transportation—are among the functions that broadly fall under the umbrella of SCM. SCM includes the integrated planning and execution of processes required to optimize the flow of materials, information, and capital.

Supply chain management is entered on a more conventional management and business strategy, whereas supply chain engineering is focused on a model-based approach, even if both have the same objectives.

Marketing channels are crucial to supply-chain management, The subjects of sustainability and risk management, among others, are the focus of current supply-chain management research.

Supply chain resilience is a key idea covered in SCM. Some claim that topics like as the “people dimension” of SCM, ethical concerns, internal integration, transparency/visibility, and human capital/talent management have not received enough attention on the research agenda thus far. SCM refers to the wide variety of tasks necessary to efficiently plan, manage, and carry out a product’s movement from raw materials to production and distribution. SCM includes coordinated planning and Demand planning, sourcing, production, inventory management, and logistics—or storage and transportation—are among the functions that broadly fall under the umbrella of SCM. SCM includes the integrated planning and execution of processes required to optimize the flow of materials, information, and capital.

Supply chain management is entered on a more conventional management and business strategy, whereas supply chain engineering is focused on a model-based approach, even if both have the same objectives.

Furniture sector market distinguishes between service and product needs when it comes to overall segmentation. The segmentation was deemed adequate by all the respondents. But no one responded in agreement. Because to cater to these sectors, the supply chain was modified. The source in the entire sector, chains are the norm. No customizing is being done place. The survey respondents understood the value of customization, Budgetary restrictions prevented any significant change in this direction.

Most organizations employ forecasting technique. The However, respondents believed that many of these predicting techniques were unscientific. 50% of respondents said the real data from the previous year and a Sales and order totals were calculated based on intuition.

All respondents agreed that demand planning and forecasting were somewhat related. The question of whether the big suppliers’ policy of transparency was addressed by the respondents’ received responses from all of them. enforced in a bad way. Here, the sole exception was whether retailer had acquired or integrated vertically into the supplier chain launched its own factory making furniture.

Information exchange in the supply chain only took place where suppliers were integrated with the retailer. The existence of electronic data exchange (EDI) systems was acknowledged by 50% of respondents between some suppliers and the organizations. This more often applied in relation to white goods and electronics. There are many gaps in the EDI systems. They are limited in their purpose to just enabling order placing and the orders are confirmed. the availability of information regarding delivery dates, the Stock, models, colours, and other options are never available. Queries regarding these matters must be performed over the phone.

Furniture sector market distinguishes between service and product needs when it comes to overall segmentation. The segmentation was deemed adequate by all the respondents. But no one responded in agreement. Because to cater to these sectors, the supply chain was modified. The source in the entire sector, chains are the norm. No customizing is being done place. The survey respondents understood the value of customization, Budgetary restrictions prevented any significant change in this direction.

Most organizations employ forecasting technique. The However, respondents believed that many of these predicting techniques were unscientific. 50% of respondents said the real data from the previous year and a Sales and order totals were calculated based on intuition.

All respondents agreed that demand planning and forecasting were somewhat related. The question of whether the big suppliers’ policy of transparency was addressed by the respondents’ received responses from all of them. enforced in a bad way. Here, the sole exception was whether retailer had acquired or integrated vertically into the supplier chain launched its own factory making furniture.

Information exchange in the supply chain only took place where suppliers were integrated with the retailer. The existence of electronic data exchange (EDI) systems was acknowledged by 50% of respondents between some suppliers and the organizations. This more often applied in relation to white goods and electronics. There are many gaps in the EDI systems. They are limited in their purpose to just enabling order placing and the orders are confirmed. the availability of information regarding delivery dates, the Stock, models, colours, and other options are never available. Queries regarding these matters must be performed over the phone.

Marketing channels are crucial to supply-chain management, The subjects of sustainability and risk management, among others, are the focus of current supply-chain management research.

Supply chain resilience is a key idea covered in SCM. Some claim that topics like as the “people dimension” of SCM, ethical concerns, internal integration, transparency/visibility, and human capital/talent management have not received enough attention on the research agenda thus far. SCM refers to the wide variety of tasks necessary to efficiently plan, manage, and carry out a product’s movement from raw materials to production and distribution. SCM includes coordinated planning and Demand planning, sourcing, production, inventory management, and logistics—or storage and transportation—are among the functions that broadly fall under the umbrella of SCM. SCM includes the integrated planning and execution of processes required to optimize the flow of materials, information, and capital.

Supply chain management is entered on a more conventional management and business strategy, whereas supply chain engineering is focused on a model-based approach, even if both have the same objectives.

Marketing channels are crucial to supply-chain management, The subjects of sustainability and risk management, among others, are the focus of current supply-chain management research.

Supply chain resilience is a key idea covered in SCM. Some claim that topics like as the “people dimension” of SCM, ethical concerns, internal integration, transparency/visibility, and human capital/talent management have not received enough attention on the research agenda thus far. SCM refers to the wide variety of tasks necessary to efficiently plan, manage, and carry out a product’s movement from raw materials to production and distribution. SCM includes coordinated planning and Demand planning, sourcing, production, inventory management, and logistics—or storage and transportation—are among the functions that broadly fall under the umbrella of SCM. SCM includes the integrated planning and execution of processes required to optimize the flow of materials, information, and capital.

Supply chain management is entered on a more conventional management and business strategy, whereas supply chain engineering is focused on a model-based approach, even if both have the same objectives.

FUNCTIONS OF SUPPLY CHAIN MANAGEMENT

- The control of material and information flows between suppliers, businesses, resellers, and end users that have value added both upstream and downstream.

- To improve the long-term performance of the individual companies and the supply chain, systematic, strategic coordination of traditional business functions and tactics across all business functions inside a specific company and across businesses within the supply chain.

- It offers the following description of a customer-focused company the connections in the supply chain must be viewed as a whole system for supply chain strategies to be effective in generating customer satisfaction at the point of delivery to the consumer.

- To reduce costs throughout the chain, needless expenses, movements, and handling must be eliminated. the key end user’s impression of value or efficiency and additional value are the main points of attention. Both efficiency and bottlenecks must be eliminated.

- The effectiveness of the entire system is measured, as well as how fairly those in the supply chain are compensated financially. The supply chain system needs to be adaptable to client needs.

- The supply chain’s major business activities being integrated to maximize value for customers and other stakeholders.

- According to the Council of Supply Chain Management Professionals, supply-chain management includes all sourcing, procurement, conversion, and logistics management planning and management (CSCMP).

- It also entails coordinating and cooperating with channel partners, who may be clients, middlemen, suppliers, or intermediaries. Demand and supply are incorporated into supply-chain management.

COMPONENTS OF SUPPLY CHAIN MANAGEMENT

- Planning: To meet client needs, businesses must properly plan and manage all of their resources. Planning, the first phase of the supply chain process, entails developing the structure and selecting the metrics that will be employed to meet corporate objectives.

- Sourcing: Companies must list their suppliers to obtain the raw materials needed to manufacture a product. Several methods to manage the supplier relationships are put into action after receiving the supplier contract.

- Making: Supply chain managers coordinate and keep an eye on tasks like acquiring inventory, producing products, inspecting them for quality, packaging them, and planning deliveries. To ensure that goods and services reach a certain standard of quality, organizations assess product quality, production output, and worker performance.

- Delivering: Often known as logistics, involves organizing customer orders, consigning cargo, planning and scheduling deliveries, billing customers, and collecting payments. To deliver goods to customers, a vehicle trail is necessary.

- Returning: To accept excess, damaged, or outdated goods, a provider needs a responsive and robust network. If the product is flawed, it must either be fixed or discarded. And if there are too many, they must be brought back to the warehouse for sale.

- Enabling: The supply chain to operate efficiently, it needs the support of ancillary services to monitor information flow throughout the chain and guarantee regulatory compliance. Finance, human resources, information technology, portfolio management, product design, quality control, and sales are some of these processes.

IMPORTANCE OF SUPPLY CHAIN MANAGEMENT

- Improved customer service

- Reduced operational costs

- Safety in society

- Possibilities for employment

OBJECTIVES OF SUPPLY CHAIN MANAGEMENT

- Maximizes operational Efficiency: The management of inventory, transportation, and logistics effectively can be difficult and requires a thorough grasp of the operations. This maximizes operational efficiency. The operational efficiency is maximized when product makers, distributors, and retailers collaborate on the supply chain system.

- Optimization of logistics and transportation: In the framework of a standalone firm, the corporation is given the roles and duties of ordering, shipping, and transportation of goods. The cost is typically higher in such a company architecture, nevertheless, because of ineffective time management and coordination. SCM keeps suppliers, wholesalers, and retailers on the same page, allowing for process optimization and smooth operation. Order automation and notifications of changes to other functionalities are implemented into the system.

- Enhancing quality: Providing clients with Value-added goods or services are a crucial goal that all supply chain participants share. Because working together with the middlemen offers quality improvements, as a result, the collaborative and coordinated supply chain establishes a method via which the business and other downstream partners in the supply chain can collect customer feedback.

BENEFITS OF SUPPLY CHAIN MANGEMENT

- Traceability

- Rationalization of the supply chain

- Strategic planning

- Compliance

- Brand Enhancement

SERVICES OF SUPPLY CHAIN MANAGEMENT

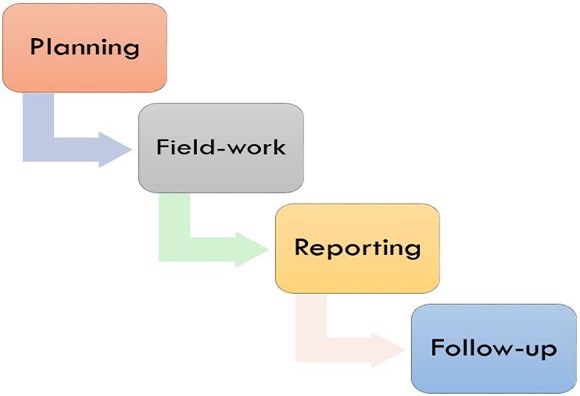

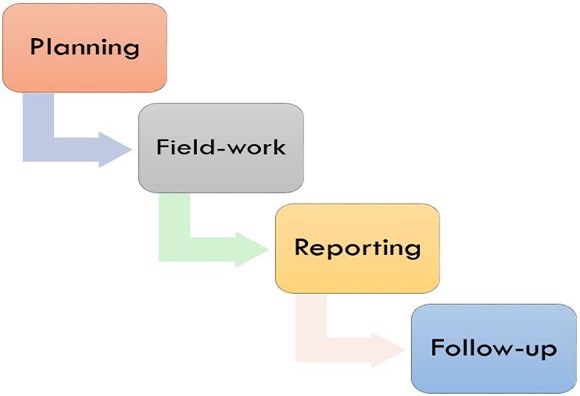

- Assessment

- Strategies

- M&A involving the supply chain

- Chain supply planning

- Logistics and Purchasing

- Profit Boosting

Furniture sector market distinguishes between service and product needs when it comes to overall segmentation. The segmentation was deemed adequate by all the respondents. But no one responded in agreement. Because to cater to these sectors, the supply chain was modified. The source in the entire sector, chains are the norm. No customizing is being done place. The survey respondents understood the value of customization, Budgetary restrictions prevented any significant change in this direction.

Most organizations employ forecasting technique. The However, respondents believed that many of these predicting techniques were unscientific. 50% of respondents said the real data from the previous year and a Sales and order totals were calculated based on intuition.

All respondents agreed that demand planning and forecasting were somewhat related. The question of whether the big suppliers’ policy of transparency was addressed by the respondents’ received responses from all of them. enforced in a bad way. Here, the sole exception was whether retailer had acquired or integrated vertically into the supplier chain launched its own factory making furniture.

Information exchange in the supply chain only took place where suppliers were integrated with the retailer. The existence of electronic data exchange (EDI) systems was acknowledged by 50% of respondents between some suppliers and the organizations. This more often applied in relation to white goods and electronics. There are many gaps in the EDI systems. They are limited in their purpose to just enabling order placing and the orders are confirmed. the availability of information regarding delivery dates, the Stock, models, colours, and other options are never available. Queries regarding these matters must be performed over the phone.

Furniture sector market distinguishes between service and product needs when it comes to overall segmentation. The segmentation was deemed adequate by all the respondents. But no one responded in agreement. Because to cater to these sectors, the supply chain was modified. The source in the entire sector, chains are the norm. No customizing is being done place. The survey respondents understood the value of customization, Budgetary restrictions prevented any significant change in this direction.

Most organizations employ forecasting technique. The However, respondents believed that many of these predicting techniques were unscientific. 50% of respondents said the real data from the previous year and a Sales and order totals were calculated based on intuition.

All respondents agreed that demand planning and forecasting were somewhat related. The question of whether the big suppliers’ policy of transparency was addressed by the respondents’ received responses from all of them. enforced in a bad way. Here, the sole exception was whether retailer had acquired or integrated vertically into the supplier chain launched its own factory making furniture.

Information exchange in the supply chain only took place where suppliers were integrated with the retailer. The existence of electronic data exchange (EDI) systems was acknowledged by 50% of respondents between some suppliers and the organizations. This more often applied in relation to white goods and electronics. There are many gaps in the EDI systems. They are limited in their purpose to just enabling order placing and the orders are confirmed. the availability of information regarding delivery dates, the Stock, models, colours, and other options are never available. Queries regarding these matters must be performed over the phone.